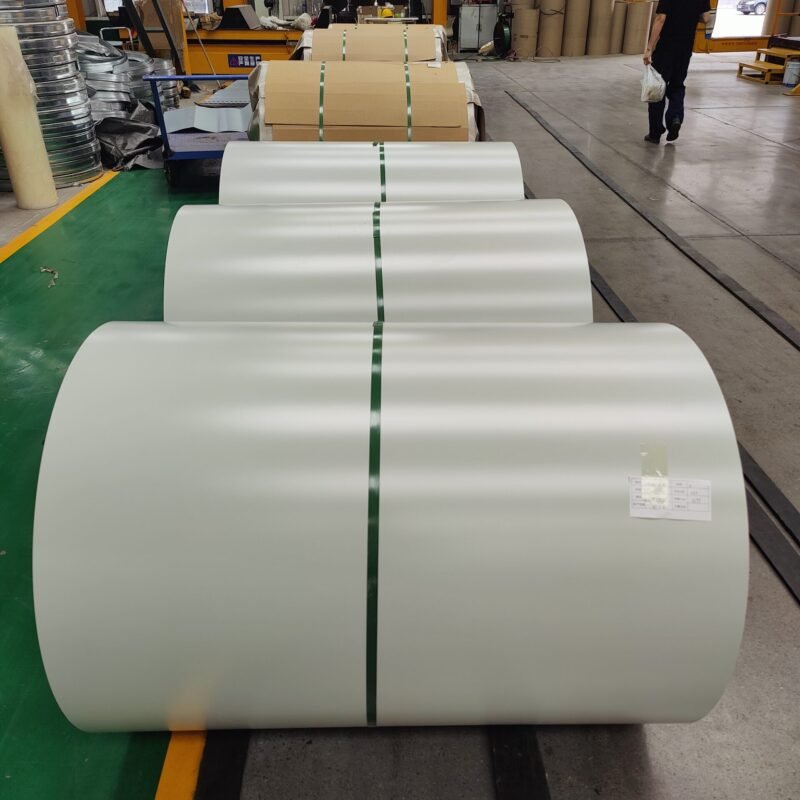

Color coated galvanzied steel coil for home appliance panel

Welding Wonders Forging Excellence Together

Color coated galvanzied steel coil for home appliance panel

- Standard: ASTM / AISI / BS / DIN / JIS / GB etc.

- Thickness:0.16-1.2mm

- Width:50mm-1500mm

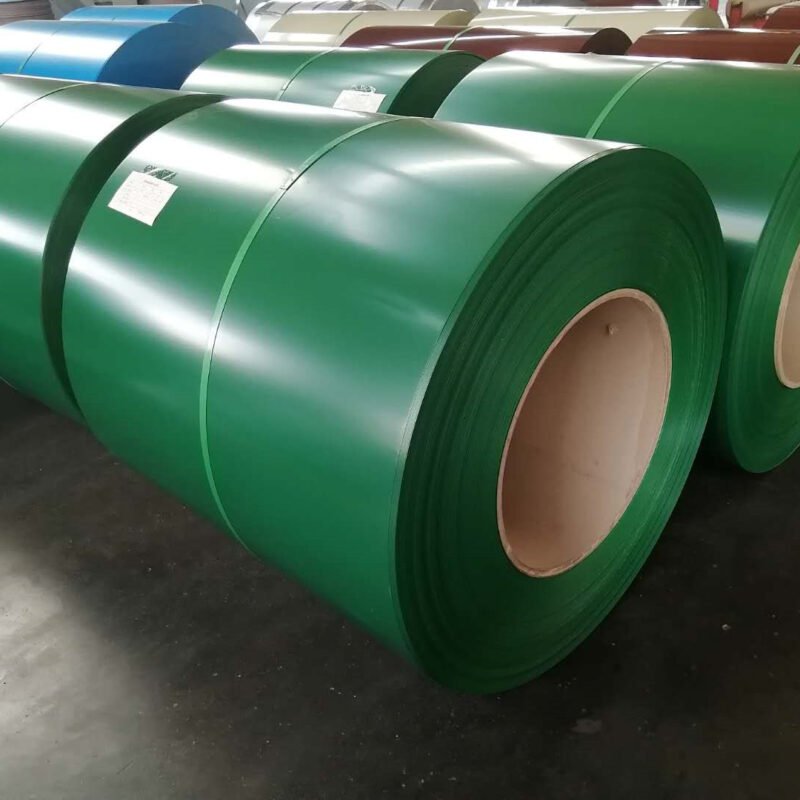

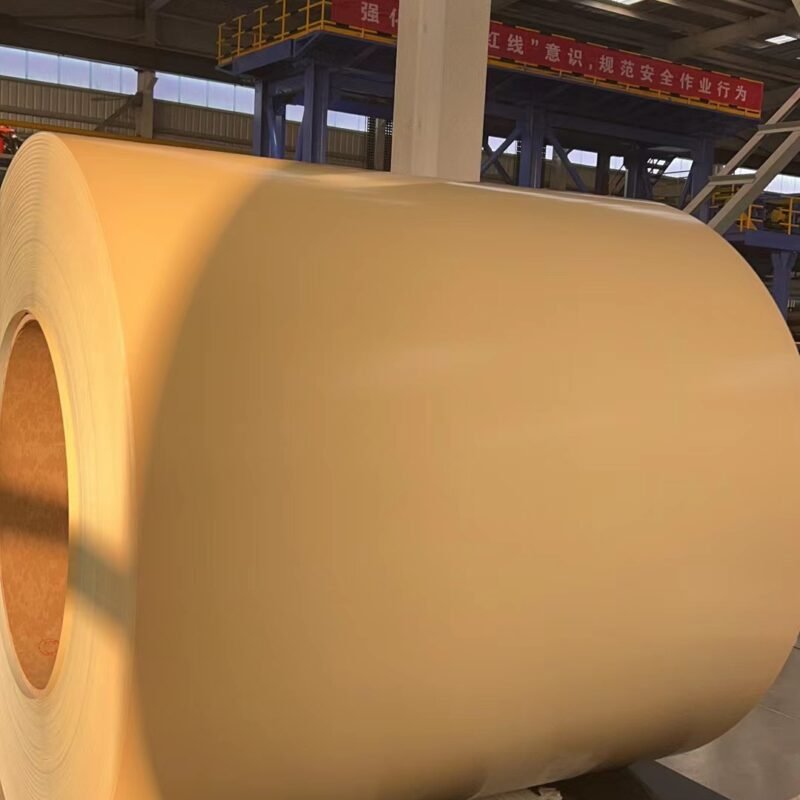

- Color: the product can be painted in any color according to the customer’s preferences and the needs of their projects

- Paint System: Polyester,HDP, SMP, PVDF

- Surface Finish:Glossy, matte, wrinkle, printed style

PRODUCTS DETAIL

Prepainted steel is a composite material made by applying a layer of organic coating or polymer film onto a metal galvalume steel substrate.It features vibrant colors and textures on the surface, combining the strength of metal with the weather resistance and decorative properties of the coating. It is widely used in construction (roofing, wall panels), home appliances and decorative materials.

Shandong Sino Metal Co., Ltd is a leading integrated company of processing & trading in China, we focus on the production and sales of color coated steel coils. Superior quality makes our products get the customer’s widely recognized.

Are you looking for Prepainted Galvalume steel coils manufacturer in China? Contact Shandong Sino Metal today and boost your brand with our Prepainted Galvalume steel coils.

What are Prepainted Galvalume steel coils? Prepainted Galvalume steel coils Introduction

Feed the aluminum-zinc base material into the coating production line. Apply primer first, then topcoat to ensure uniformity and adhesion of the coating. Bake and cure the coating to form a durable color coating.The color coated aluminum-zinc coils widely used in construction, home appliances and other fields.

Color Coated Aluminum-zinc Steel Coil Advantages & Features

Advantages

- Superior Corrosion Resistance

The Aluminum-zinc (55% Al, 43.4% Zn,1.6% Si) combined with organic paint provides 2-6X better corrosion resistance than galvanized steel, ideal for coastal/industrial zones.

- High-Temperature Tolerance

Withstands up to 600°C(short-term), suitable for heat-exposed applications (e.g.,chimneys,oven exteriors)

- Aesthetic Versatility

Available in PVDF/SMP or polyester coatings with diverse colors( RAL/Pantone standards), enhancing architectural design.

- Lightweight & High Strength

Advanced high-strength steel (AHSS) grades (e.g., HX420LAD) reduce weight by 15-20% while maintaining structural integrity.

- Extended Service Life

Proven 25+ years lifespan in field tests (ISO 12944 C5-M class), minimizing replacement costs.

Features

- Multi-Layer Structure

Base metal (CRCA steel) + Alu-Zinc alloy layer + primer/topcoat system

- Continuous Coating Process

Hot-dip galvanizing followed by coil coating ensures precise thickness control

- Formability

Compatible with roll forming/punching, certified for complex profiles.

- Eco-Friendly

Fully recyclable (GRS certified), low-VOC coatings meet LEED/BREEAM requirements.

- Cross-Industry Utility

Widely used in construction (sandwich panels), appliances (washing machine drums), and automotive (HVAC components).