Scénarios d'application des bobines d'acier galvanisé quadrillées

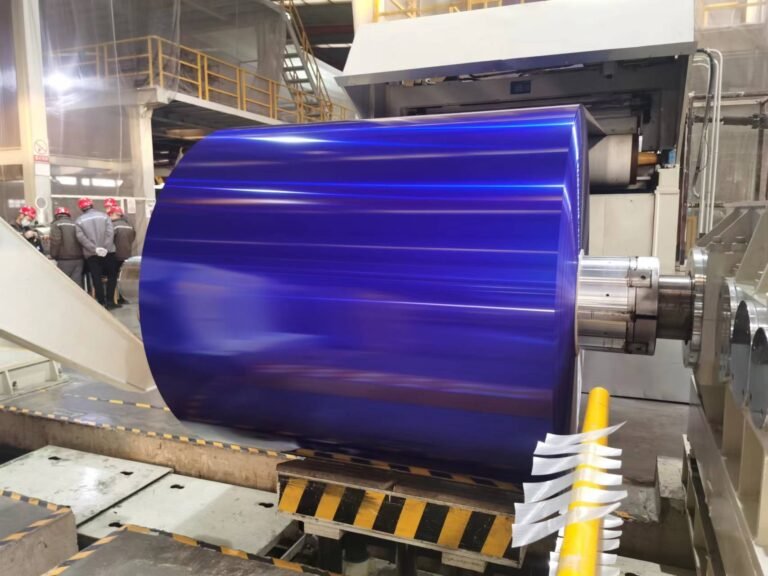

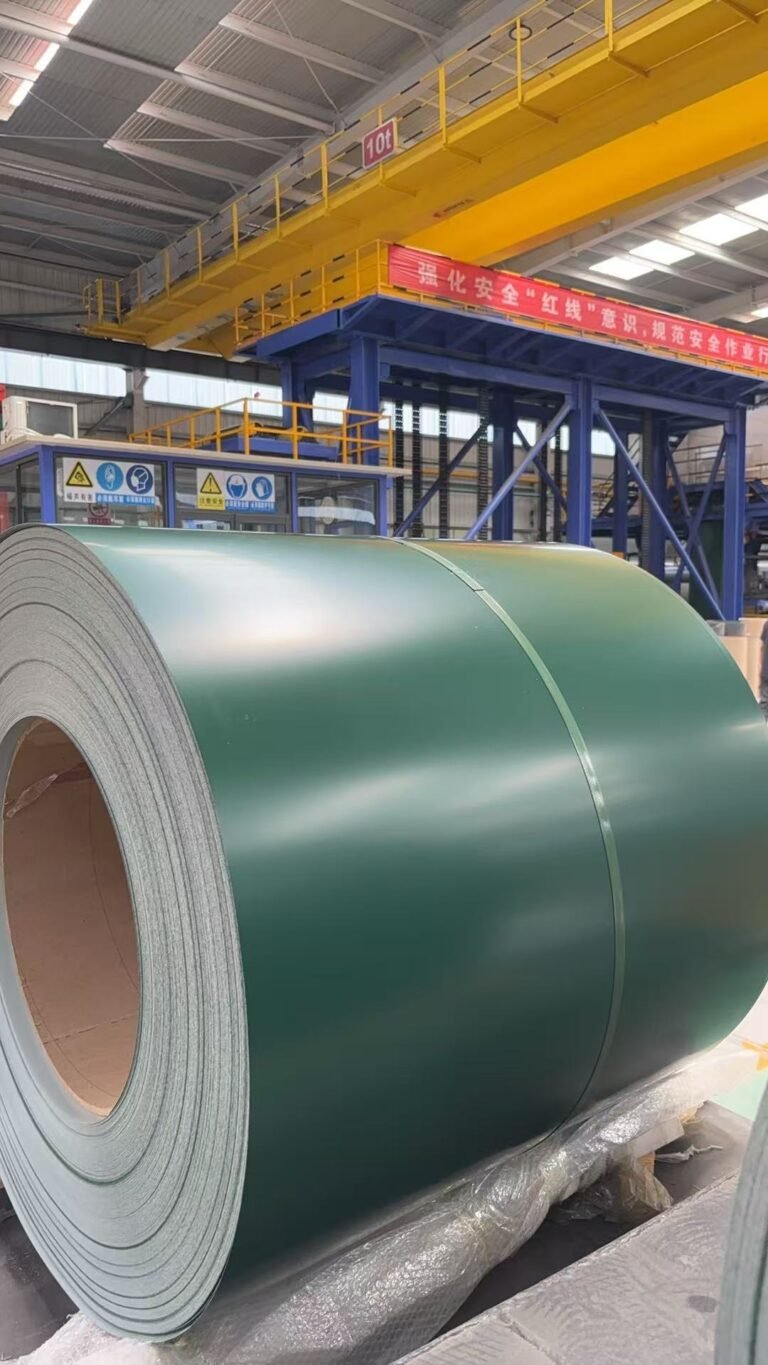

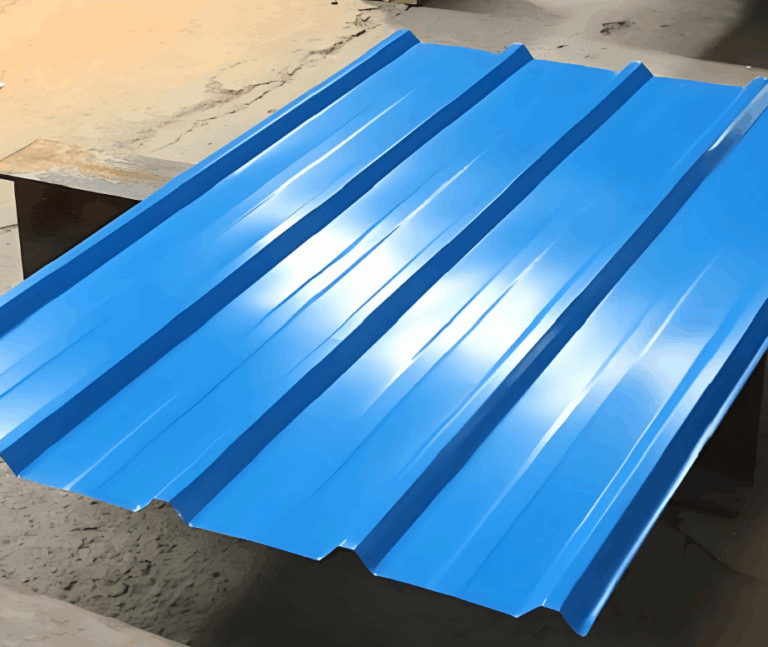

Les bobines d'acier galvanisé quadrillées sont des matériaux polyvalents qui trouvent des applications dans diverses industries en raison de leurs propriétés uniques, notamment la résistance à la corrosion, la durabilité et l'attrait esthétique. Voici quelques exemples d'applications courantes des bobines d'acier galvanisé quadrillées : 1. Construction et bâtiment 2. Automobile et transport 3. Applications industrielles 4. Infrastructures et installations publiques 5. Commerce de détail et espaces commerciaux 6. Applications maritimes 7. Maison...