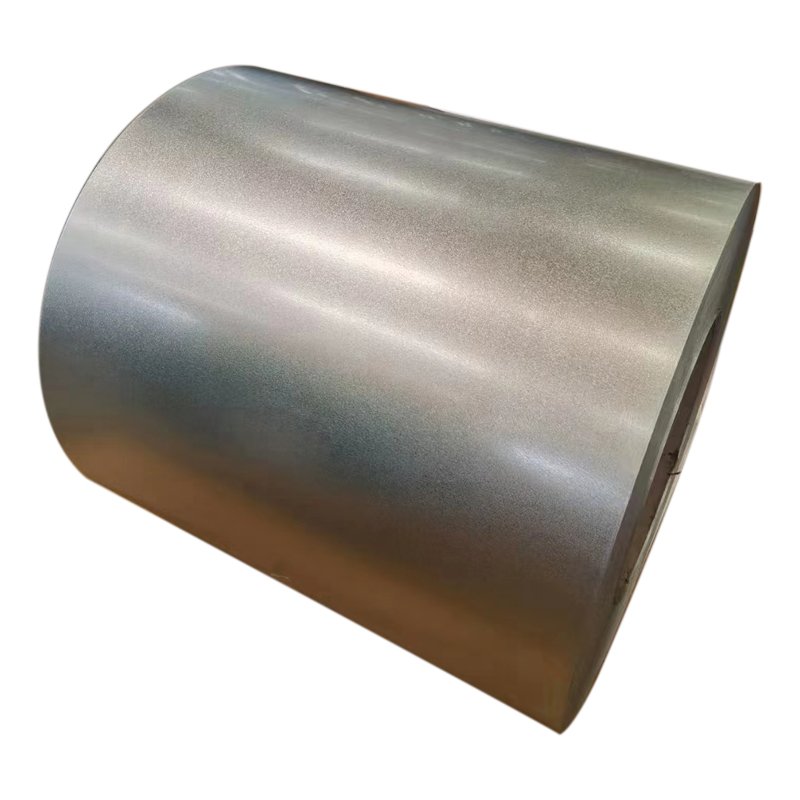

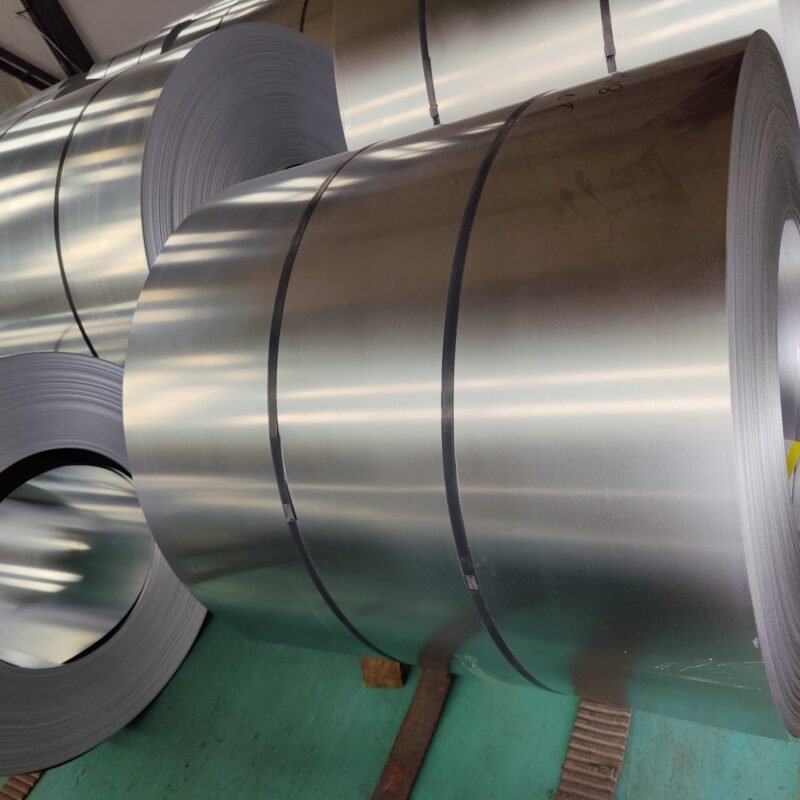

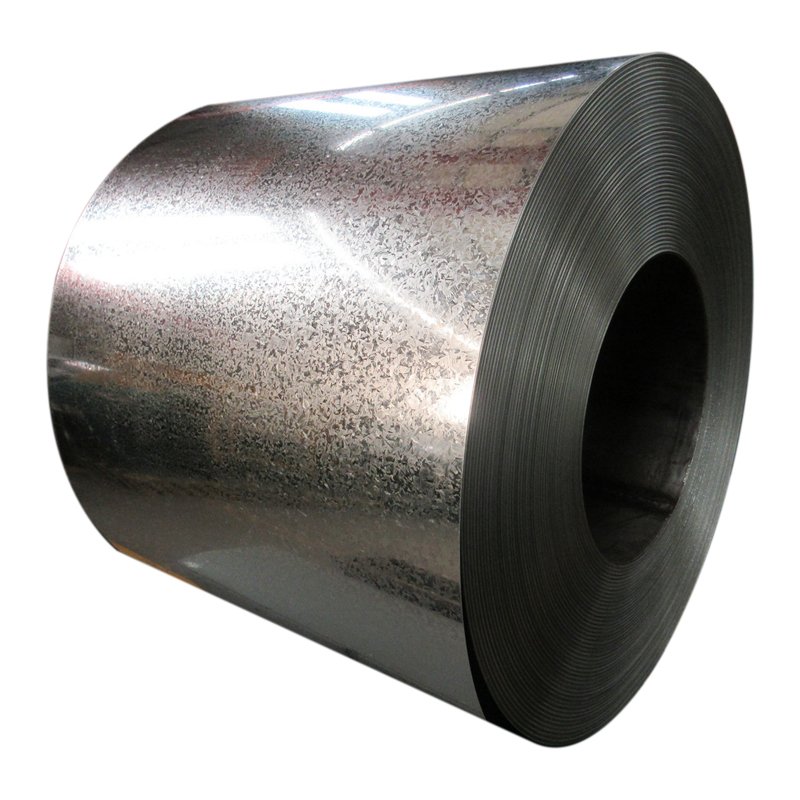

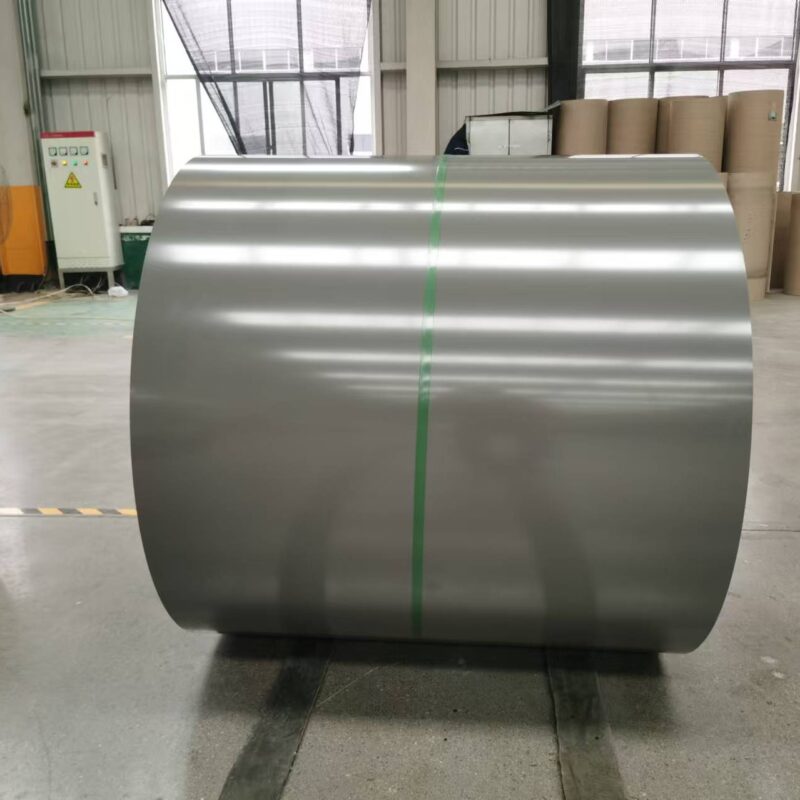

Bobina de acero galvanizado (GI)

Welding Wonders Forjando juntos la excelencia

DETALLE DE PRODUCTOS

El galvanizado es un proceso de revestimiento metálico que aplica una capa protectora de zinc a sustratos de acero o hierro para evitar la corrosión mediante la protección de ánodos de sacrificio. Los métodos más comunes son el galvanizado en caliente (inmersión del acero en zinc fundido) y el electrogalvanizado (deposición electrolítica de zinc). El acero galvanizado combina la resistencia del acero con las propiedades anticorrosivas del zinc, y se utiliza ampliamente en la construcción, torres de transmisión eléctrica, piezas de automoción, tuberías e infraestructuras exteriores.

Detalles del producto

| Artículo | Bobina GI |

| Estándar | AISI; ASTM; BS; GB; JIS |

| Sustrato | Acero laminado en caliente/ Acero laminado en frío |

| Espesor | 0,12 mm-2 mm |

| Anchura | 50 mm-1500 mm |

| Revestimiento | 20g/㎡-275g/㎡ |

| Peso de la bobina | según sus necesidades |

| Estructura de la superficie | Ángulo cero; Ángulo pequeño;Ángulo normal;Ángulo grande |

| Paquete | Paquete de exportación estándar o según sus necesidades |

Bobina de acero galvanizado Ventajas y características

- Excelente resistencia a la corrosión: La capa de zinc forma una densa película protectora sobre la superficie metálica, impidiendo eficazmente que el aire, la humedad y otras sustancias corrosivas entren en contacto con el metal base, lo que prolonga enormemente la vida útil del producto.

- Buena propiedad decorativa: Los productos galvanizados suelen tener un aspecto brillante y uniforme. Pueden realizarse distintos tratamientos superficiales, como la pasivación y el revestimiento de aceite, según las necesidades para conseguir un mejor efecto decorativo y satisfacer los requisitos estéticos de los distintos escenarios de aplicación.

- Fuerte adherencia: Existe una fuerte fuerza de unión entre la capa de zinc y el metal base, que puede soportar cierto grado de deformación sin desprenderse, lo que garantiza la integridad y eficacia de la capa protectora.

- Coste elevado - eficacia: En comparación con otros métodos de tratamiento anticorrosión, como el niquelado y el cromado, el galvanizado tiene un coste relativamente bajo y puede proporcionar una protección fiable, con una elevada relación coste-rendimiento.

- Buen rendimiento de procesamiento: Los productos galvanizados siguen teniendo un buen rendimiento de procesamiento y pueden someterse a diversas operaciones de procesamiento, como estampado, doblado y soldadura, sin causar daños graves a la capa de zinc.

Áreas de aplicación

- Industria de la construcción: Se utiliza en tejados, paredes, puertas y ventanas, conductos de ventilación, etc. Puede resistir eficazmente la erosión del viento y la lluvia, prolongar la vida útil de los componentes de los edificios y proporcionar un aspecto estético. Por ejemplo, las chapas de acero galvanizado se utilizan a menudo como material de revestimiento de los tejados de los edificios.

- Industria del automóvil: Los productos galvanizados se utilizan en muchas partes de los automóviles, como la carrocería, el chasis y los componentes. Por ejemplo, las chapas de acero galvanizado se utilizan en la fabricación de carrocerías para mejorar la resistencia a la corrosión y a los impactos de la carrocería y prolongar la vida útil del vehículo.

- Industria energética: Las instalaciones eléctricas, como las torres de transmisión, los postes de servicios públicos y las bandejas de cables, suelen adoptar un tratamiento de galvanización para evitar que el metal se oxide y corroa en el entorno exterior y garantizar el funcionamiento seguro y estable de las instalaciones eléctricas.

- Fabricación mecánica: Después de galvanizar varias piezas mecánicas y carcasas de equipos, no sólo puede mejorar la resistencia a la corrosión, sino también mejorar la calidad de la apariencia y mejorar la calidad general del producto.

- Sector de los electrodomésticos: Las carcasas exteriores y los componentes internos de electrodomésticos como frigoríficos, aparatos de aire acondicionado y lavadoras suelen utilizar chapas de acero galvanizado o alambres de acero galvanizado para mejorar la resistencia a la corrosión y la durabilidad de los productos y ofrecer un buen aspecto.