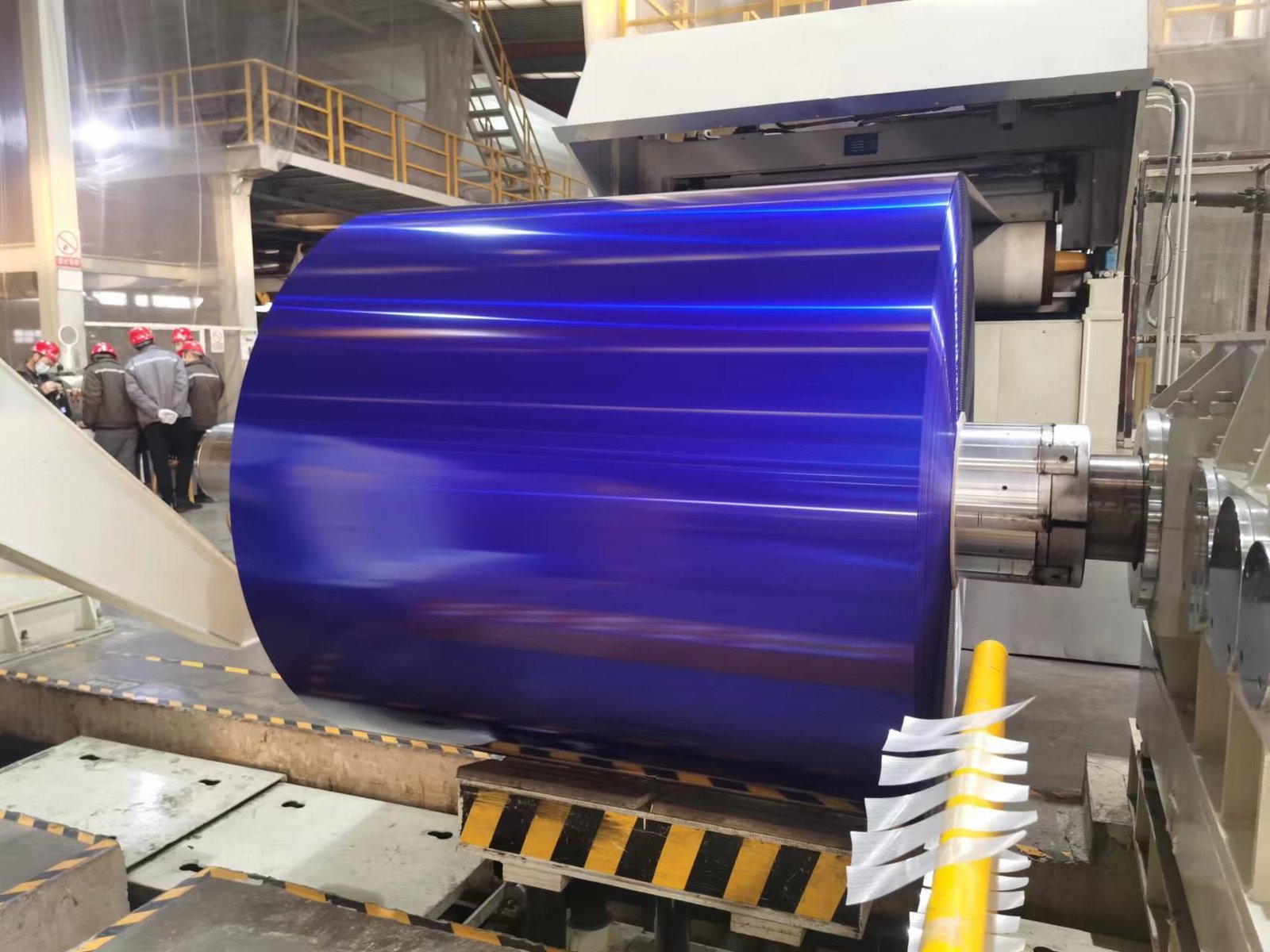

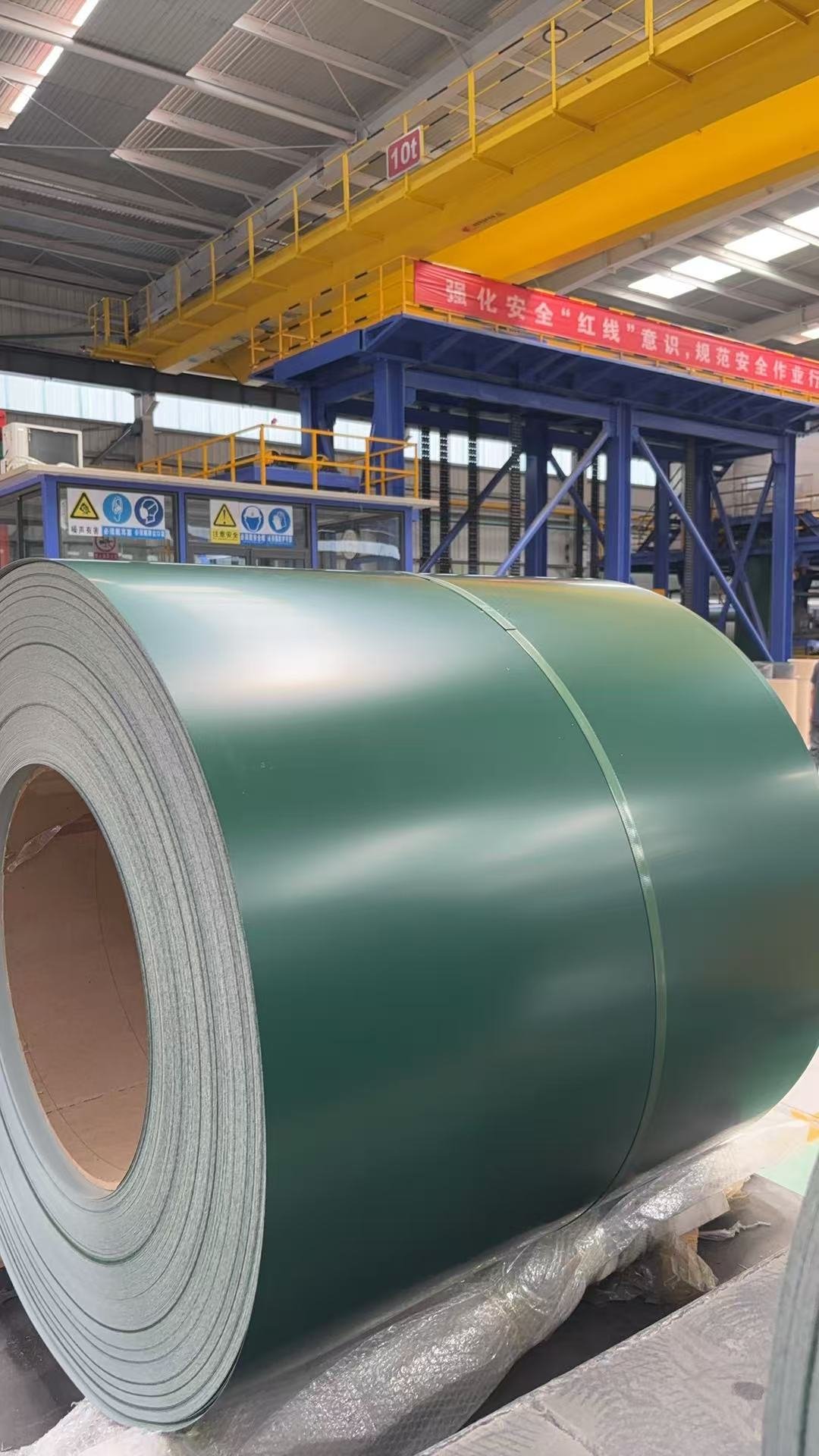

Pattern galvanized steel coil, as a special type of steel that combines galvanizing technology and pattern design, has shown significant advantages in multiple fields. Its advantages can be elaborated in detail from five dimensions: anti-corrosion performance, anti slip and load-bearing capacity, aesthetics and practicality, economy and environmental friendliness, and processing and installation convenience

Pattern galvanized steel coil, as a special type of steel that combines galvanizing technology and pattern design, has shown significant advantages in multiple fields. Its advantages can be elaborated in detail from five dimensions: anti-corrosion performance, anti slip and load-bearing capacity, aesthetics and practicality, economy and environmental friendliness, and processing and installation convenience

1、 Excellent anti-corrosion performance

Galvanized layer protection: The patterned galvanized steel coil is hot-dip galvanized to form a uniform and dense zinc layer on the surface of the coil. As a sacrificial anode, the zinc layer preferentially corrodes to protect the steel substrate, effectively resisting harsh environments such as moisture, salt spray, and chemical corrosion, and extending its service life.

Long term stability: The zinc layer forms a metallurgical bond with the steel substrate, which is not easily peeled off or detached, ensuring long-term anti-corrosion effect. Even in extreme environments such as coastal areas or highly polluted industrial zones, patterned galvanized steel coils can still maintain stable anti-corrosion performance.

Low maintenance cost: Due to its excellent anti-corrosion performance, patterned galvanized steel coils do not require frequent anti-corrosion treatment during use, reducing maintenance costs and downtime, and improving economic benefits.

2、 Enhanced anti slip and load-bearing capacity

Anti slip design: The surface of the patterned galvanized steel coil is designed with specific patterns (such as diamond, bean, round bean, etc.), which increase the friction on the surface of the steel coil, effectively prevent personnel or objects from sliding, and improve safety.

Load bearing strengthening: The pattern design not only enhances the anti slip performance of the steel coil, but also improves its load-bearing capacity by increasing the contact area and dispersing pressure. This enables patterned galvanized steel coils to withstand heavy loads without deformation, making them suitable for load-bearing scenarios such as storage shelves, logistics turnover boxes, etc.

Structural stability: The pattern design of the patterned galvanized steel coil also enhances its structural stability, making it less prone to deformation or damage when subjected to external impact, and improving its reliability of use.

3、 The combination of aesthetics and practicality

Beautiful appearance: The pattern design of the patterned galvanized steel coil endows it with a unique aesthetic appearance, which can meet the requirements of different scenarios for material appearance. Whether it is exterior wall decoration in the field of architecture, roof panels, or shell components in home appliance manufacturing, patterned galvanized steel coils can provide beautiful solutions.

Versatile functions: patterned galvanized steel coils not only have a beautiful appearance, but also have various practical functions. For example, in the field of architecture, it can be used as a structural material while providing anti-corrosion and anti slip protection; In the field of warehousing and logistics, it can be used as a material for shelves and turnover boxes to improve load-bearing capacity and safety.

Customized service: The pattern shape and size of patterned galvanized steel coils can be customized according to customer needs to meet personalized requirements in different scenarios. This customized service makes patterned galvanized steel coils more competitive in the market.

4、 Dual advantages of economy and environmental friendliness

High cost-effectiveness: Although the unit price of patterned galvanized steel coils may be slightly higher than ordinary galvanized steel coils, their long-term anti-corrosion performance and enhanced load-bearing capacity enable them to reduce replacement frequency and maintenance costs during use, thereby reducing overall costs. In addition, the long service life of patterned galvanized steel coils further improves their cost-effectiveness.

Environmentally friendly materials: Galvanizing process is an environmentally friendly metal surface treatment technology that does not produce harmful substances or pollute the environment. At the same time, patterned galvanized steel coils can be recycled and reused, meeting the requirements of sustainable development. In today’s increasingly environmentally conscious world, the market demand for patterned galvanized steel coils continues to grow.

Energy saving and emission reduction: The production process of patterned galvanized steel coils is relatively energy-efficient, and can reduce material waste and energy consumption caused by corrosion and damage during use. This helps to reduce carbon emissions and promote the development of green manufacturing.

5、 Convenience of processing and installation

Easy to process: patterned galvanized steel coils have good processing performance and can be processed through cutting, bending, stamping and other processes to meet the needs of different shapes and sizes. This makes the patterned galvanized steel coil more flexible and efficient in the manufacturing process.

Easy installation: The installation process of patterned galvanized steel coils is relatively simple, without the need for complex tools and equipment. Its lightweight and easy to handle characteristics make installation work faster and safer. In addition, the standardized production of patterned galvanized steel coils has also improved installation efficiency and accuracy.

Strong compatibility: patterned galvanized steel coils can be combined with other materials (such as wood, plastic, etc.) to form composite structures, further improving their performance and applicability. This compatibility enables patterned galvanized steel coils to be widely used in multiple fields.1、 Excellent anti-corrosion performance

Galvanized layer protection: The patterned galvanized steel coil is hot-dip galvanized to form a uniform and dense zinc layer on the surface of the coil. As a sacrificial anode, the zinc layer preferentially corrodes to protect the steel substrate, effectively resisting harsh environments such as moisture, salt spray, and chemical corrosion, and extending its service life.

Long term stability: The zinc layer forms a metallurgical bond with the steel substrate, which is not easily peeled off or detached, ensuring long-term anti-corrosion effect. Even in extreme environments such as coastal areas or highly polluted industrial zones, patterned galvanized steel coils can still maintain stable anti-corrosion performance.

Low maintenance cost: Due to its excellent anti-corrosion performance, patterned galvanized steel coils do not require frequent anti-corrosion treatment during use, reducing maintenance costs and downtime, and improving economic benefits.

2、 Enhanced anti slip and load-bearing capacity

Anti slip design: The surface of the patterned galvanized steel coil is designed with specific patterns (such as diamond, bean, round bean, etc.), which increase the friction on the surface of the steel coil, effectively prevent personnel or objects from sliding, and improve safety.

Load bearing strengthening: The pattern design not only enhances the anti slip performance of the steel coil, but also improves its load-bearing capacity by increasing the contact area and dispersing pressure. This enables patterned galvanized steel coils to withstand heavy loads without deformation, making them suitable for load-bearing scenarios such as storage shelves, logistics turnover boxes, etc.

Structural stability: The pattern design of the patterned galvanized steel coil also enhances its structural stability, making it less prone to deformation or damage when subjected to external impact, and improving its reliability of use.

3、 The combination of aesthetics and practicality

Beautiful appearance: The pattern design of the patterned galvanized steel coil endows it with a unique aesthetic appearance, which can meet the requirements of different scenarios for material appearance. Whether it is exterior wall decoration in the field of architecture, roof panels, or shell components in home appliance manufacturing, patterned galvanized steel coils can provide beautiful solutions.

Versatile functions: patterned galvanized steel coils not only have a beautiful appearance, but also have various practical functions. For example, in the field of architecture, it can be used as a structural material while providing anti-corrosion and anti slip protection; In the field of warehousing and logistics, it can be used as a material for shelves and turnover boxes to improve load-bearing capacity and safety.

Customized service: The pattern shape and size of patterned galvanized steel coils can be customized according to customer needs to meet personalized requirements in different scenarios. This customized service makes patterned galvanized steel coils more competitive in the market.

4、 Dual advantages of economy and environmental friendliness

High cost-effectiveness: Although the unit price of patterned galvanized steel coils may be slightly higher than ordinary galvanized steel coils, their long-term anti-corrosion performance and enhanced load-bearing capacity enable them to reduce replacement frequency and maintenance costs during use, thereby reducing overall costs. In addition, the long service life of patterned galvanized steel coils further improves their cost-effectiveness.

Environmentally friendly materials: Galvanizing process is an environmentally friendly metal surface treatment technology that does not produce harmful substances or pollute the environment. At the same time, patterned galvanized steel coils can be recycled and reused, meeting the requirements of sustainable development. In today’s increasingly environmentally conscious world, the market demand for patterned galvanized steel coils continues to grow.

Energy saving and emission reduction: The production process of patterned galvanized steel coils is relatively energy-efficient, and can reduce material waste and energy consumption caused by corrosion and damage during use. This helps to reduce carbon emissions and promote the development of green manufacturing.

5、 Convenience of processing and installation

Easy to process: patterned galvanized steel coils have good processing performance and can be processed through cutting, bending, stamping and other processes to meet the needs of different shapes and sizes. This makes the patterned galvanized steel coil more flexible and efficient in the manufacturing process.

Easy installation: The installation process of patterned galvanized steel coils is relatively simple, without the need for complex tools and equipment. Its lightweight and easy to handle characteristics make installation work faster and safer. In addition, the standardized production of patterned galvanized steel coils has also improved installation efficiency and accuracy.

Strong compatibility: patterned galvanized steel coils can be combined with other materials (such as wood, plastic, etc.) to form composite structures, further improving their performance and applicability. This compatibility enables patterned galvanized steel coils to be widely used in multiple fields.