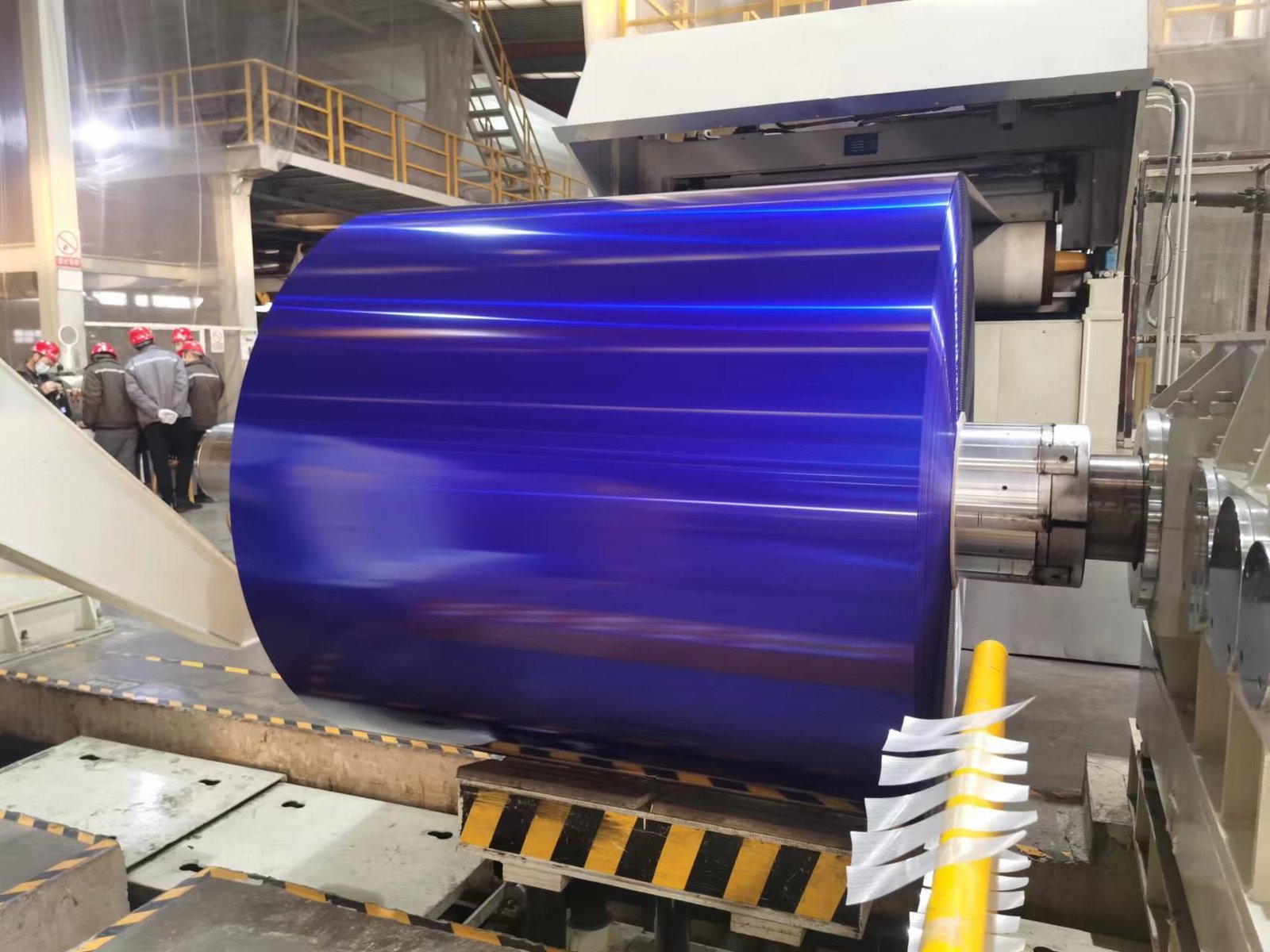

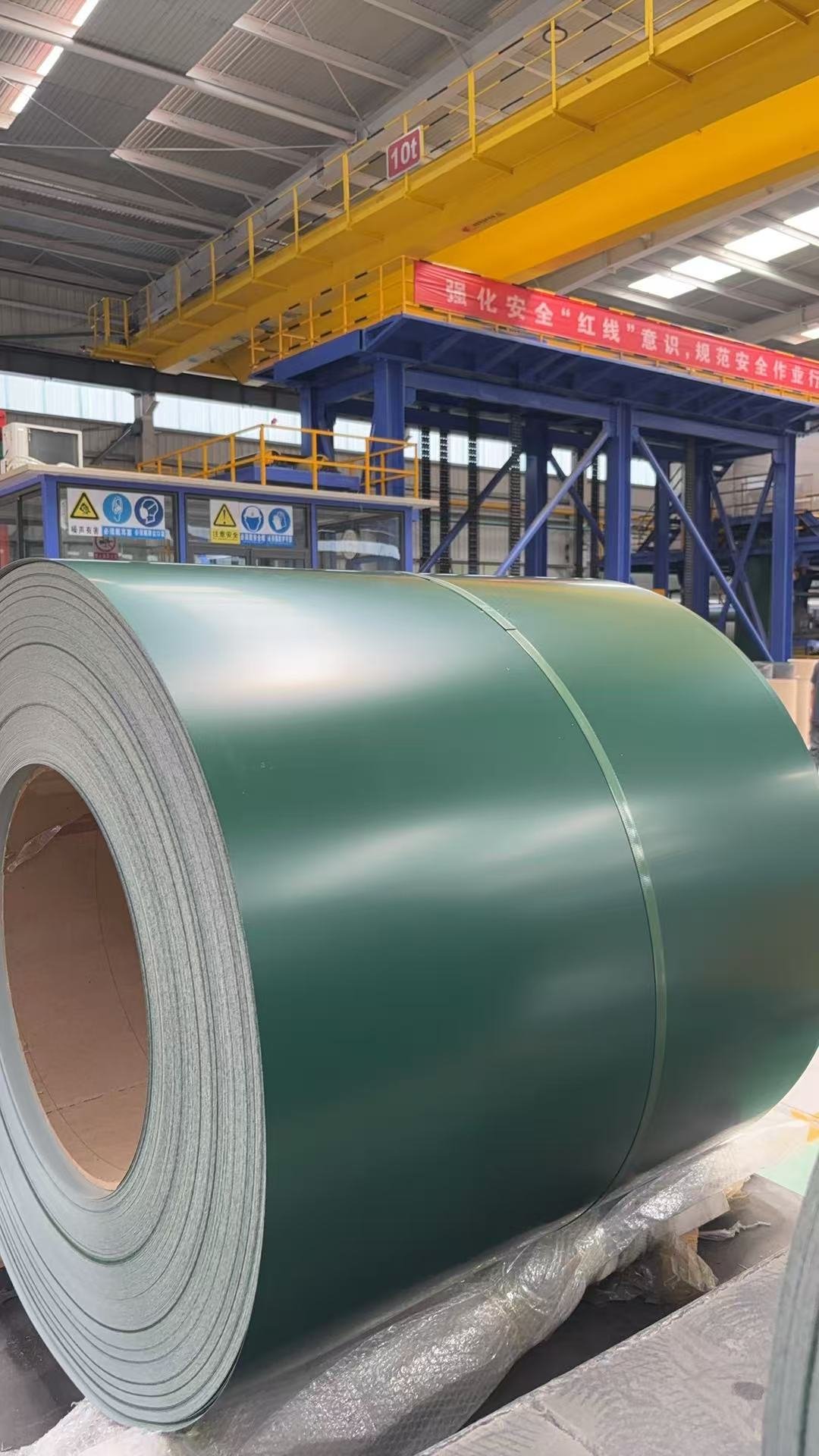

Color-painted galvalume steel coil combines the durability and corrosion resistance of galvalume steel with the aesthetic appeal of color coatings. Here are the key characteristics of color-painted galvalume steel coil:

- Galvalume Coating

Material Composition: Galvalume is a combination of zinc (55%), aluminum (43.4%), and silicon (1.6%) coating applied to steel. This blend provides excellent corrosion resistance.

Corrosion Resistance: The galvalume coating offers superior protection against rust and corrosion compared to traditional galvanized steel, especially in harsh environments.

Longevity: The coating prolongs the lifespan of the steel, making it ideal for outdoor applications and areas exposed to moisture.

- Color Coating

Aesthetic Appeal: The color coating on the galvalume surface provides an attractive finish. It’s available in a wide range of colors, including matte, gloss, and metallic finishes.

Variety of Finishes: Common finishes include polyester, polyvinylidene fluoride (PVDF), and silicone-modified polyester (SMP), each offering varying levels of UV resistance, durability, and gloss.

Customizable: The coating can be tailored to specific color requirements, which is great for architectural, residential, or industrial applications.

- Durability

Weather Resistance: The color coating enhances the steel’s resistance to UV rays, preventing color fading or chalking.

Scratch and Abrasion Resistance: Depending on the type of coating used, color-painted galvalume coils can resist surface damage from scratching, making it suitable for high-traffic areas.

Impact Resistance: The coating can also offer protection against minor impacts or dents, though it may vary based on the specific paint system.

- Thermal Reflectivity

Energy Efficiency: The reflective properties of the color coating can reduce heat absorption, helping to keep buildings cooler and potentially lowering cooling costs.

Solar Reflective Index (SRI): Some finishes are designed with high SRI, which reflects more sunlight and reduces heat buildup in buildings.

- Application Versatility

Construction Industry: Widely used for roofing, siding, and cladding due to its aesthetic qualities, weather resistance, and long lifespan.

Automotive Industry: Used for parts that require both durability and appearance, such as body panels.

Home Appliances: Color-coated galvalume steel is often used in products like refrigerators, air conditioning units, and washing machines.

- Environmental Impact

Eco-Friendly: Galvalume steel is recyclable, and many coatings are designed to be low in volatile organic compounds (VOCs), making it a more environmentally responsible choice compared to other materials.

Low Maintenance: Due to the durable coating, it requires less maintenance over time compared to uncoated or other types of painted steel.

- Cost

Affordable Option: Compared to stainless steel or aluminum, color-painted galvalume steel coils offer a more cost-effective solution while maintaining high durability and aesthetics.

Long-Term Savings: Its longevity and low maintenance requirements can translate into cost savings in the long run.

- Flexibility in Fabrication

Ease of Forming: The material can be easily cut, bent, and shaped without damaging the coating, allowing for versatility in design and manufacturing.

Compatibility with Various Processes: Color-painted galvalume coils can be used with various fabrication methods, including punching, stamping, and roll-forming.

In summary, color-painted galvalume steel coil is known for its strength, corrosion resistance, and aesthetic appeal. It offers a balance of durability, energy efficiency, and versatility, making it suitable for a variety of applications in construction, automotive, and appliance manufacturing.